Focus on metal whole system data construction

Create industry authoritative brand portal

【CBC Lithium Key Material】Member Hot Research Report;

Trend insights, industry hot spots: not to be missed!

【CBC】Lithium Battery Industry Chain Production Cost and Enterprise Profit Assessment in 2023 and Forecast in 2024

Made by: CBC Lithium Research Institute & Business Research and Big Data Center

Production time: March 2024

Report content introduction

"【CBC】Lithium Battery Industry Chain Production Cost and Enterprise Profit Assessment in 2023 and Forecast in 2024 " is a custom report carefully designed by CBC Lithium Research Institute, CBC is equipped with a team of professional analysts to investigate the cost and profit situation from the mainstream representative enterprises of the industry through first-hand research and industry market communication. The cost account and cost classification of the whole product production link of the lithium battery industry chain are studied, the cost influencing factors are analyzed, and the profit margin is evaluated according to the current market situation of the product.

From the perspective of the market, the report makes a comprehensive and powerful analysis of the output, price, demand, import and export volume, operating rate analysis, downstream application development and domestic price trend of the lithium battery market in the past three years, and focuses on the direct material costs, direct labor costs, manufacturing expenses and other aspects of the lithium battery products. It also predicts and forecasts the future market development, price quotation and cost of lithium battery, and helps enterprises make correct decisions.

The report also collects and collates important industry policies, important industry information, enterprise dynamics and other news and information of the lithium battery and its industrial chain products industry, summarizes and deeply analyzes various matters affecting market costs and profit quotations, and at the same time for investment institutions, accurately calculate the average cost of the industry, analyze the changes in profitability, and obtain the best return on investment!

Report research dimension analysis

For this set of research reports, we will conduct research and analysis from three dimensions:

Ø Dimension 1: Comprehensive analysis of lithium battery and its industry chain products application industry status quo at home and abroad, major consumer applications, industry mainstream production process and flow.

² Industrial chain structure, industry status, application consumption field, traditional application and emerging material application analysis

² Industry production process and flow introduction

Ø Dimension 2: Cost and profit research of raw materials and accessories related to lithium battery production and overall subjects

² Clearly defines the cost of lithium battery products, and analyzes and studies the market structure of raw materials required for production

² The profit of the overall cost of lithium battery is collected, and the influencing factors are explained in detail

Ø Dimension 3: Lithium battery and its industry chain products application consumption pattern future trend, price market forecast and production and operation enterprise investment competitiveness and profitability assessment

² Lithium battery and its industry chain products market influencing factors inventory, supply and demand comparison, future development of main application fields, national macro policies and study on new opportunities for industrial development in the context of the development of new materials in science and technology

² Study the qualitative trend and quantitative model of lithium battery and its industry chain products, and predicts the future market of lithium battery and its industry chain products based on first-hand enterprise research and in-depth industry analysis

Report characteristics

Authoritative and true data information: CBC is equipped with a team of professional analysts, who track core value data in real time through first-hand research and industry market communication, and professionally collect the latest information on the industry chain, which is detailed and reliable;

Long-term continuous tracking of data: long-term continuous tracking of the market dynamics of production, sales and transactions of enterprises in different markets of lithium battery and its industrial chain products;

Comprehensive depth of content: Combining upstream and downstream core data at home and abroad, such as price, production, import and export trade, consumption and other indicators, in-depth analysis of product market changes in all dimensions, interpretation of hot events, summarize the development of the law, according to the domestic and international industry end-use applications and consumer demand status, etc., in-depth from the demand side of the exclusive analysis, based on the supply and demand pattern of the market, scientific and objective forecasts of the future market trend, to provide the development of the industry and investment advice and other conclusions.

Introduction of key indicators of research report information

Ø Product research and industrial chain scope

² Core products: Lithium battery

² Raw materials: cathode material, anode material, electrolyte, separator, auxiliary materials (copper foil, aluminum foil), etc.

² Core products: ternary lithium battery, lithium iron phosphate battery, lithium cobaltate battery, lithium manganate battery, etc.

² Terminal application: new energy field, energy storage field, 3C field, other fields

Ø Industry research information and data indicators in the report

² Industry development background: industrial chain structure, industry status, application consumption field, traditional application and emerging material application analysis, etc.

² Technology and processing method: processing technology, process characteristics, production flow, equipment and so on

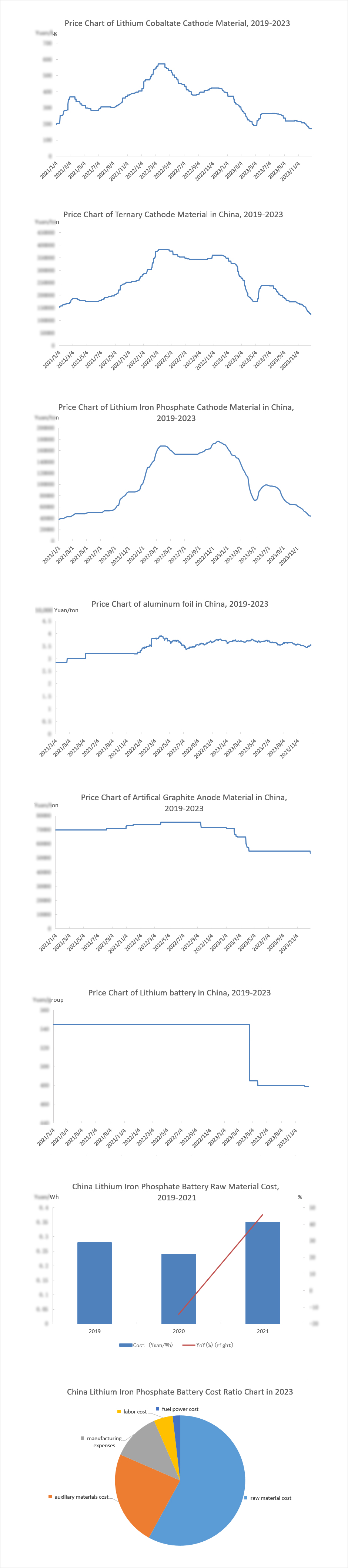

² Price research and monitoring: product price, historical market, price fluctuation and market analysis, price industry chain comparison, price forecast, etc.

² Industrial chain supply and demand research: production capacity, output, import and export, supply, consumption demand, cost, profit, process technology, etc.

² Research and mapping of practicing enterprises: enterprises list, production situation of enterprises, analysis of supply chain of enterprises, future development plans, assessment of production costs, operating revenues and profits of enterprises, etc.

² Cost and profit: production cost, cost subjects, cost analysis, operating profit, profitability assessment, market space, competitive assessment and future prediction, etc.

² Procurement enterprise research and mapping: enterprise information, purchased products, grade indicators, application fields, procurement channels, payment and settlement requirements, import and China domestic procurement ratio, etc.

² Industry development prospect forecast: market influence factor analysis, industry development, production capacity development, supply and demand forecast, terminal material development, product grade index and applied consumption research, future strategy development, policy environment, supply and demand impact, new industry regulations and new policies, alternative material development, market trend and price forecast, etc.

² Enterprise product positioning, investment and profit return analysis: enterprise product positioning, supply chain deployment suggestions, enterprise cost, enterprise automation information development and cost control space, operating profit, investment opportunities, strategic development decision suggestions, etc.

Ø Report analysis time

² Historical data: 2021~2023, a total of 3 years

² Forecast data: 2024, a total of 1 year

【CBC】Lithium Battery Industry Chain Production Cost and Enterprise Profit Assessment in 2023 and Forecast in 2024

Report structure and outline introduction:

Part 1: Overview of the basic development of lithium battery industry

1 Introduction to the foundation of lithium battery industry

2 Diagram and introduction of lithium battery industry chain structure

2.1 Overall industry structure

2.2 Upstream raw materials

2.3 Downstream material products

3 Research on application fields of lithium battery

3.1 Application of lithium battery in traditional consumption field

3.2 Application fields of lithium battery materials for emerging materials development

4 Overview of lithium battery domestic and international development status

4.1 Overview of the development of the world lithium battery industry

4.2 Overview of the development of lithium battery industry in China

Part 2: Introduction of the main products and production process of lithium battery

5 Global lithium battery production advanced production process introduction

5.1 Introduction to the main lithium battery product types

5.2 General introduction of mainstream process classification

5.3 Advanced introduction and characteristic analysis of each process

5.4 Research on process comparison and competitiveness

6 The current domestic lithium battery production mainstream technology and process introduction

6.1 Introduction to the main lithium battery product types

6.2 General introduction of mainstream process classification

6.3 Advanced introduction and characteristic analysis of different types of lithium battery

6.3.1 Production process and process characteristics of ternary lithium battery

6.3.2 Production process and process characteristics of lithium iron phosphate battery

6.3.3 Production process and process characteristics of lithium manganate battery

6.3.4 Production process and process characteristics of lithium cobaltate battery

6.3.5 Other lithium battery production processes and process characteristics

6.4 Research on the comparison and competitiveness of various processes

Part 3: Introduction of the basic definition of the production cost of the whole industry chain of lithium battery

7 Basic definition of production cost accounts and components of the whole lithium battery industry chain

7.1 Composition of various types of cost accounts of lithium battery whole industrial chain production

7.1.1 Composition of complete production cost account

7.1.2 Composition of direct production cost account

7.2 Various types of cost accounts and basic definitions of lithium battery whole industrial chain production

7.2.1 Complete production cost account and basic definition

7.2.2 Direct production cost account and basic definition

Part 4: Lithium battery production cost detail accounting research

8 Research on detailed accounting of production cost of ternary lithium battery

8.1 Ternary lithium battery cost accounting

8.1.1 Direct materials

8.1.1.1 Raw material cost

8.1.1.2 Auxiliary materials cost

8.1.2 Fuel power cost

8.1.3 Direct labor

8.1.4 Manufacturing expenses

8.1.5 Period fee

8.1.5.1 Management fees

8.1.5.2 Selling expenses

8.1.5.3 Financial expenses

8.1.6 Cost of various taxes and fees

8.2 Summary of cost accounts

8.3 Analysis of influencing factors of various cost accounts

8.3.1 Influencing factors and forecast of raw material cost

8.3.2 Influencing factors and prediction of auxiliary materials cost

8.3.3 Influencing factors and forecast of fuel power cost

8.3.4 Influencing factors and forecast of labor cost

8.3.5 Influencing factors and forecast of manufacturing expenses

9 Research on detailed accounting of production cost of lithium iron phosphate battery

9.1 Accounting of the costs of lithium iron phosphate batteries

9.1.1 Direct materials

9.1.1.1 Raw material cost

9.1.1.2 Auxiliary materials cost

9.1.2 Fuel power cost

9.1.3 Direct labor

9.1.4 Manufacturing expenses

9.1.5 Period fee

9.1.5.1 Management fees

9.1.5.2 Selling expenses

9.1.5.3 Financial expenses

9.1.6 Cost of various taxes and fees

9.2 Summary of cost accounts

9.3 Analysis of influencing factors of various cost accounts

9.3.1 Influencing factors and forecast of raw material cost

9.3.2 Influencing factors and prediction of auxiliary materials cost

9.3.3 Influencing factors and forecast of fuel power cost

9.3.4 Influencing factors and forecast of labor cost

9.3.5 Influencing factors and forecast of manufacturing expenses

10 Research on detailed accounting of production cost of lithium manganate battery

10.1 lithium manganate battery cost accounting

10.1.1 Direct materials

10.1.1.1 Raw material cost

10.1.1.2 Auxiliary materials cost

10.1.2 Fuel power cost

10.1.3 Direct labor

10.1.4 Manufacturing expenses

10.1.5 Period fees

10.1.5.1 Management expenses

10.1.5.2 Selling expenses

10.1.5.3 Finance charges

10.1.6 Cost of various taxes and fees

10.2 Summary of cost accounts

10.3 Analysis of influencing factors of various cost accounts

10.3.1 Influencing factors and forecast of raw material cost

10.3.2 Influencing factors and prediction of auxiliary materials cost

10.3.3 Influencing factors and forecast of fuel power cost

10.3.4 Influencing factors and forecast of labor cost

10.3.5 Influencing factors and forecast of manufacturing expenses

11 Research on detailed accounting of production cost of lithium cobaltate battery

11.1 Accounting of the costs of lithium cobaltate batteries

11.1.1 Direct materials

11.1.1.1 Raw material cost

11.1.1.2 Auxiliary materials cost

11.1.2 Fuel power cost

11.1.3 Direct labor

11.1.4 Manufacturing expenses

11.1.5 Period fees

11.1.5.1 Management expenses

11.1.5.2 Selling expenses

11.1.5.3 Financial expenses

11.1.6 Cost of various taxes and fees

11.2 Summary of cost accounts

11.3 Analysis of influencing factors of various cost

11.3.1 Influencing factors and forecast of raw material cost

11.3.2 Influencing factors and prediction of auxiliary materials cost

11.3.3 Influencing factors and forecast of fuel power cost

11.3.4 Influencing factors and forecast of labor cost

11.3.5 Influencing factors and forecast of manufacturing expenses

12. Comparative analysis of costs of different types of lithium battery manufacturers

Part 5: Upstream raw material production cost detail accounting research

13 Research on detailed accounting of production cost of cathode materials

13.1 Research on detailed accounting of production cost of ternary cathode materials

13.1.1 Ternary cathode material cost accounting

13.1.2 Cost accounts summary

13.1.3 Analysis of influencing factors of various cost accounts

13.1.3.1 Influencing factors and forecast of raw material cost

13.1.3.2 Influencing factors and prediction of auxiliary materials cost

13.1.3.3 Influencing factors and forecast of fuel power cost

13.1.3.4 Influencing factors and forecast of labor cost

13.1.3.5 Influencing factors and forecast of manufacturing expenses

13.2 Research on detailed accounting of production cost of lithium iron phosphate cathode material

13.2.1 Lithium iron phosphate cathode material cost accounting

13.2.2 Cost accounts summary

13.2.3 Analysis of influencing factors of various cost accounts

13.2.3.1 Influencing factors and forecast of raw material cost

13.2.3.2 Influencing factors and prediction of auxiliary materials cost

13.2.3.3 Influencing factors and forecast of fuel power cost

13.2.3.4 Influencing factors and forecast of labor cost

13.2.3.5 Influencing factors and forecast of manufacturing expenses

13.3 Research on detailed accounting of production cost of lithium manganate cathode material

13.3.1 lithium manganate cathode material cost accounting

13.3.2 Cost accounts summary

13.3.3 Analysis of influencing factors of various cost accounts

13.3.3.1 Influencing factors and forecast of raw material cost

13.3.3.2 Influencing factors and prediction of auxiliary materials cost

13.3.3.3 Influencing factors and forecast of fuel power cost

13.3.3.4 Influencing factors and forecast of labor cost

13.3.3.5 Influencing factors and forecast of manufacturing expenses

13.4 Research on detailed accounting of production cost of lithium cobaltate cathode material

13.4.1 lithium cobaltate cathode material cost accounting

13.4.2 Cost accounts summary

13.4.3 Analysis of influencing factors of various cost accounts

13.4.3.1 Influencing factors and forecast of raw material cost

13.4.3.2 Influencing factors and prediction of auxiliary materials cost

13.4.3.3 Influencing factors and forecast of fuel power cost

13.4.3.4 Influencing factors and forecast of labor cost

13.4.3.5 Influencing factors and forecast of manufacturing expenses

13.5 Comparative analysis of enterprise costs in different feature

14 Research on detailed accounting of production cost of anode materials

14.1 Research on detailed accounting of production cost of artificial graphite anode materials

14.1.1 Accounting of the cost of artificial graphite anode materials

14.1.2 Cost accounts summary

14.1.3 Analysis of influencing factors of various cost accounts

14.1.3.1 Influencing factors and forecast of raw material cost

14.1.3.2 Influencing factors and prediction of auxiliary materials cost

14.1.3.3 Influencing factors and forecast of fuel power cost

14.1.3.4 Influencing factors and forecast of labor cost

14.1.3.5 Influencing factors and forecast of manufacturing expenses

14.2 Research on detailed accounting of production cost of natural graphite anode materials

14.2.1 Accounting of the cost of natural graphite anode materials

14.2.2 Cost accounts summary

14.2.3 Analysis of influencing factors of various cost accounts

14.2.3.1 Influencing factors and forecast of raw material cost

14.2.3.2 Influencing factors and forecast of auxiliary materials cost

14.2.3.3 Influencing factors and forecast of fuel power cost

14.2.3.4 Influencing factors and forecast of labor cost

14.2.3.5 Influencing factors and forecast of manufacturing expenses

14.3 Comparative analysis of enterprise costs in different characteristic

15 Research on detailed accounting of electrolyte production cost

15.1 Research on detailed accounting of production cost of ternary electrolyte

15.1.1 Electrolyte cost accounting

15.1.2 Cost accounts summary

15.1.3 Analysis of influencing factors of various cost accounts

15.1.3.1 Influencing factors and forecast of raw material cost

15.1.3.2 Influencing factors and forecast of auxiliary materials cost

15.1.3.3 Influencing factors and forecast of fuel power cost

15.1.3.4 Influencing factors and forecast of labor cost

15.1.3.5 Influencing factors and forecast of manufacturing expenses

15.2 Research on detailed accounting of production cost of lithium iron phosphate electrolyte

15.2.1 Electrolyte cost accounting

15.2.2 Cost accounts summary

15.2.3 Analysis of influencing factors of various cost accounts

15.2.3.1 Influencing factors and forecast of raw material cost

15.2.3.2 Influencing factors and forecast of auxiliary materials cost

15.2.3.3 Influencing factors and forecast of fuel power cost

15.2.3.4 Influencing factors and forecast of labor cost

15.2.3.5 Influencing factors and forecast of manufacturing expenses

15.3 Research on detailed accounting of production cost of lithium manganate electrolyte

15.3.1 Electrolyte cost accounting

15.3.2 Cost accounts summary

15.3.3 Analysis of influencing factors of various cost accounts

15.3.3.1 Influencing factors and forecast of raw material cost

15.3.3.2 Influencing factors and forecast of auxiliary materials cost

15.3.3.3 Influencing factors and forecast of fuel power cost

15.3.3.4 Influencing factors and forecast of labor cost

15.3.3.5 Influencing factors and forecast of manufacturing expenses

15.4 Research on detailed accounting of production cost of lithium cobaltate electrolyte

15.4.1 Electrolyte cost accounting

15.4.2 Cost accounts summary

15.4.3 Analysis of influencing factors of various cost accounts

15.4.3.1 Influencing factors and forecast of raw material cost

15.4.3.2 Influencing factors and forecast of auxiliary materials cost

15.4.3.3 Influencing factors and forecast of fuel power cost

15.4.3.4 Influencing factors and forecast of labor cost

15.4.3.5 Influencing factors and forecast of manufacturing expenses

16 Research on detailed accounting of separator production cost

16.1 Research on detailed accounting of separator production cost

16.1.1 Separator cost account accounting

16.1.2 Cost account summary

16.1.3 Analysis of influencing factors of various cost accounts

16.1.3.1 Influencing factors and forecast of raw material cost

16.1.3.2 Influencing factors and forecast of auxiliary materials cost

16.1.3.3 Influencing factors and forecast of fuel power cost

16.1.3.4 Influencing factors and forecast of labor cost

16.1.3.5 Influencing factors and forecast of manufacturing expenses

17 Research on detailed accounting of production cost of auxiliary materials for lithium battery

17.1 Research on detailed accounting of copper foil production cost

17.1.1 Accounting of copper foil cost and expense

17.1.2 Cost account summary

17.1.3 Analysis of influencing factors of various cost accounts

17.1.3.1 Influencing factors and forecast of raw material cost

17.1.3.2 Influencing factors and forecast of auxiliary materials cost

17.1.3.3 Influencing factors and forecast of fuel power cost

17.1.3.4 Influencing factors and forecast of labor cost

17.1.3.5 Influencing factors and forecast of manufacturing expenses

17.2 Research on detailed accounting of aluminum foil production cost

17.2.1 Accounting of aluminum foil cost

17.2.2 Cost accounts summary

17.2.3 Analysis of influencing factors of various cost accounts

17.2.3.1 Influencing factors and forecast of raw material cost

17.2.3.2 Influencing factors and forecast of auxiliary materials cost

17.2.3.3 Influencing factors and forecast of fuel power cost

17.2.3.4 Influencing factors and forecast of labor cost

17.2.3.5 Influencing factors and forecast of manufacturing expenses

Part 6: Lithium battery production process material price trend analysis

18 Analysis of raw material price trend in the production process of lithium battery

18.1 Cathode material price trend analysis

18.1.1 Price trend analysis of lithium iron phosphate cathode material

18.1.2 Price trend analysis of ternary cathode material

18.1.3 Price trend analysis of lithium manganate cathode material

18.1.4 Price trend analysis of lithium cobaltate cathode material

18.2 Anode material price trend analysis

18.2.1 Price trend analysis of artificial graphite anode materials

18.2.2 Price trend analysis of natural graphite anode materials

18.3 Analysis of electrolyte price trend

18.3.1 Price trend analysis of lithium iron phosphate electrolyte

18.3.2 Price trend analysis of ternary electrolyte

18.3.3 Price trend analysis of lithium manganate electrolyte

18.3.4 Price trend analysis of lithium cobaltate electrolyte

18.4 Separator price trend analysis

19 Analysis of the price trend of auxiliary materials in the production process of lithium battery

19.1 Copper foil price trend analysis

19.2 Aluminum foil price trend analysis

20 Analysis of fuel power price trend in the production process of lithium battery

20.1 Analysis of industrial water price trend

20.2 Analysis of industrial electricity price trend

Part 7: Profit assessment of lithium battery whole industry chain enterprise

21 Lithium battery enterprises profit assessment

21.1 Profit assessment of ternary battery enterprises

21.2 Profit assessment of lithium iron phosphate battery enterprises

21.3 Profit assessment of lithium manganate battery enterprises

21.4 Profit assessment of lithium cobaltate battery enterprises

22 Upstream raw material enterprises profit assessment

22.1 Profit assessment of cathode material enterprises

22.1.1 Profit assessment of lithium iron phosphate cathode material enterprises

22.1.2 Profit assessment of ternary cathode material enterprises

22.1.3 Profit assessment of lithium manganate cathode material enterprises

22.1.4 Profit assessment of lithium cobaltate cathode material enterprises

22.2 Profit assessment of anode material enterprises

22.2.1 Profit assessment of artificial graphite anode material enterprises

22.2.2 Profit assessment of natural graphite anode material enterprises

22.3 Profit assessment of electrolyte enterprises

22.3.1 Profit assessment of lithium iron phosphate electrolyte enterprises

22.3.2 Profit assessment of ternary electrolyte enterprises

22.3.3 Profit assessment of lithium manganate electrolyte enterprises

22.3.4 Profit assessment of lithium cobaltate electrolyte enterprise

22.4 Profit assessment of separator enterprises

22.5 Profit assessment of copper foil enterprises

22.6 Profit assessment of aluminum foil enterprises

23 Comparative analysis of profit linkage of industrial chain

23.1 Comparative analysis of profit linkage between cathode material production enterprises and lithium battery enterprises

23.2......

Part 8: Cost and profit forecast of the whole industry chain of lithium battery in 2024

24 Lithium battery cost and profit analysis and forecast

24.1 Cost and profit analysis and forecast of ternary lithium battery

24.1.1 Cost analysis and forecast of ternary lithium battery

24.1.1.1 Analysis and summary of influencing factors of cost

24.1.1.2 Trend analysis of each factor in 2024

24.1.1.3 Overall cost forecast for 2024

24.1.2 Profit analysis and prediction of ternary lithium battery

24.1.2.1 Analysis and summary of influencing factors of profit

24.1.2.2 Trend analysis of various factors in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

24.1.2.3 Overall cost forecast for 2024

24.2 Cost and profit analysis and forecast of lithium iron phosphate battery

24.2.1 Cost analysis and forecast of lithium iron phosphate battery

24.2.1.1 Analysis and summary of influencing factors of cost

24.2.1.2 Trend analysis of each factor in 2024

24.2.1.3 Overall cost forecast for 2024

24.2.2 Profit analysis and forecast of lithium iron phosphate battery

24.2.2.1 Analysis and summary of influencing factors of profit

24.2.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

24.2.2.3 Overall cost forecast for 2024

24.3 Cost and profit analysis and forecast of lithium manganate battery

24.3.1 Cost analysis and prediction of lithium manganate battery

24.3.1.1 Analysis and summary of influencing factors of cost

24.3.1.2 Trend analysis of each factor in 2024

24.3.1.3 Overall cost forecast for 2024

24.3.2 Profit analysis and prediction of lithium manganate battery

24.3.2.1 Analysis and summary of influencing factors of profit

24.3.2.2 Trend analysis of various factors in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

24.3.2.3 Overall cost forecast for 2024

24.4 Cost and profit analysis and forecast of lithium cobaltate battery

24.4.1 Cost analysis and forecast of lithium cobaltate battery

24.4.1.1 Analysis and summary of influencing factors of cost

24.4.1.2 Trend analysis of each factor in 2024

24.4.1.3 Overall cost forecast for 2024

24.4.2 Profit analysis and forecast of lithium cobaltate battery

24.4.2.1 Analysis and summary of influencing factors of profit

24.4.2.2 Trend analysis of various factors in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

24.4.2.3 Overall cost forecast for 2024

25 Analysis and forecast of upstream raw material product cost and profit

25.1 Cost and profit analysis and forecast of cathode materials

25.1.1 Cost analysis and forecast of cathode materials

25.1.1.1 Analysis and summary of influencing factors of cost

25.1.1.2 Trend analysis of each factor in 2024

25.1.1.3 Overall cost forecast for 2024

25.1.2 Profit analysis and forecast of cathode materials

25.1.2.1 Analysis and summary of influencing factors of profit

25.1.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.1.2.3 Overall cost forecast for 2024

25.2 Anode material cost and profit analysis and forecast

25.2.1 Cost analysis and prediction of anode materials

25.2.1.1 Analysis and summary of influencing factors of cost

25.2.1.2 Trend analysis of each factor in 2024

25.2.1.3 Overall cost forecast for 2024

25.2.2 Profit analysis and prediction of anode materials

25.2.2.1 Analysis and summary of influencing factors of profit

25.2.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.2.2.3 Overall cost forecast for 2024

25.3 Analysis and forecast of electrolyte cost and profit

25.3.1 Analysis and forecast of electrolyte cost

25.3.1.1 Analysis and summary of influencing factors of cost

25.3.1.2 Trend analysis of each factor in 2024

25.3.1.3 Overall cost forecast for 2024

25.3.2 Profit analysis and forecast of electrolyte

25.3.2.1 Analysis and summary of influencing factors of profit

25.3.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.3.2.3 Overall cost forecast for 2024

25.4 Separator cost and profit analysis and forecast

25.4.1 Separator cost analysis and forecast

25.4.1.1 Analysis and summary of influencing factors of cost

25.4.1.2 Trend analysis of each factor in 2024

25.4.1.3 Overall cost forecast for 2024

25.4.2 Separator profit analysis and forecast

25.4.2.1 Analysis and summary of influencing factors of profit

25.4.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.4.2.3 Overall cost forecast for 2024

25.5 Copper foil cost and profit analysis and forecast

25.5.1 Copper foil cost analysis and forecast

25.5.1.1 Analysis and summary of influencing factors of cost

25.5.1.2 Trend analysis of each factor in 2024

25.5.1.3 Overall cost forecast for 2024

25.5.2 Profit analysis and forecast of copper foil

25.5.2.1 Analysis and summary of influencing factors of profit

25.5.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.5.2.3 Overall cost forecast for 2024

25.6 Aluminum foil cost and profit analysis and forecast

25.6.1 Aluminum foil cost analysis and forecast

25.6.1.1 Analysis and summary of influencing factors of cost

25.6.1.2 Trend analysis of each factor in 2024

25.6.1.3 Overall cost forecast for 2024

25.6.2 Aluminum foil profit analysis and forecast

25.6.2.1 Analysis and summary of influencing factors of profit

25.6.2.2 Trend analysis of each factor in 2024 and initiatives taken by enterprises to reduce costs and increase efficiency

25.6.2.3 Overall cost forecast for 2024

Part 9: Cost control and operating profit improvement methods and measures of lithium battery and industrial chain enterprises

26 Lithium battery industry cost control measures to reduce costs and increase efficiency

26.1 Ternary lithium battery industry cost control, cost reduction and efficiency measures

26.1.1 Measures to reduce costs and increase efficiency in direct production costs

26.1.2 Measures to reduce cost and increase efficiency in complete cost

26.2 Lithium iron phosphate battery industry cost control, cost reduction and efficiency measures

26.2.1 Measures to reduce costs and increase efficiency in direct production costs

26.2.2 Measures to reduce cost and increase efficiency in complete cost

26.3 Lithium manganate battery industry cost control measures to reduce costs and increase efficiency

26.3.1 Measures to reduce costs and increase efficiency in direct production costs

26.3.2 Measures to reduce cost and increase efficiency in complete cost

26.4 Lithium cobaltate battery industry cost control measures to reduce costs and increase efficiency

26.4.1 Measures to reduce costs and increase efficiency in direct production costs

26.4.2 Measures to reduce cost and increase efficiency in complete cost

27 Upstream raw material production enterprises cost control, cost reduction and efficiency increase measures

27.1 Measures for cost control, cost reduction and efficiency increase of cathode material production enterprises

27.1.1 Measures to reduce costs and increase efficiency in direct production costs

27.1.2 Measures to reduce costs and increase efficiency in complete cost

27.2 Measures for cost control, cost reduction and efficiency increase of anode material manufacturers

27.2.1 Measures to reduce costs and increase efficiency in direct production costs

27.2.2 Measures to reduce cost and increase efficiency in complete cost

27.3 Measures for cost control, cost reduction and efficiency increase of electrolyte production enterprises

27.3.1 Measures to reduce costs and increase efficiency in direct production costs

27.3.2 Cost-saving and cost-enhancing initiatives in complete cost

27.4 Measures for cost control, cost reduction and efficiency increase of separator production enterprises

27.4.1 Measures to reduce costs and increase efficiency in direct production costs

27.4.2 Measures to reduce costs and increase efficiency in complete cost

27.5 Measures for cost control, cost reduction and efficiency increase of aluminum foil production enterprises

27.5.1 Measures to reduce costs and increase efficiency in direct production costs

27.5.2 Cost-saving and cost-enhancing initiatives in complete cost

27.6 Measures for cost control, cost reduction and efficiency increase of copper foil production enterprises

27.6.1 Measures to reduce costs and increase efficiency in direct production costs

27.6.2 Measures to reduce cost and increase efficiency in complete cost

Appendix:

1 Lithium battery related policy summary

2 Lithium battery industry related standard summary

3 Lithium battery industry key news summary

4 Lithium battery industry technology summary

5 Dynamic summary of lithium battery manufacturers

6 Dynamic summary of enterprises in the field of lithium battery terminal consumption

Results of the report provided to you

² Detailed industry research reports and underlying EXCEL data package, intuitive data charts;

² Underlying data package will include: all visualization charts in the report, all underlying data bearers for the analytical study;

² In the report, all data citations and research sources and reference materials will be introduced in detail; If there is any assessment data, the assessment method and the assessment basis will be introduced in detail; For reference;

² Reports are submitted by offline email, which can be downloaded and viewed locally

Ø Report Information and Trial Readings:

Selected contents of the report

1 Overview of lithium battery domestic and international development status

1.1 Overview of the development of the world lithium battery industry

The global lithium battery is mainly distributed in the 'tripartite confrontation' state of China, Japan and South Korea, from the perspective of development history, in the last decade of the last century, almost all industries were concentrated in Japan, and then began to spread to China and South Korea. The first decade of this century is the process of China and South Korea's lithium battery industry catching up with Japan. The second decade of this century has opened the process of China's lithium battery industry surpassing Japan and South Korea. Due to the state's strong support for the new energy vehicle industry, since 2013, China's electric vehicle and lithium new energy industry has developed rapidly, and by 2015, China's electric vehicle production and sales began to occupy half of the world. Driven by the demand for electric vehicles, in just a few years, China's lithium-ion battery and related materials and raw materials industry has achieved a comprehensive surpass of Japan and South Korea in scale, and its manufacturing capacity and technical capacity have also made great progress toward the high-end product market.

The popularity of electronic devices thanks to the application of lithium battery, but also achieved the outbreak of lithium battery industry chain, notebook computers, mobile phones, tablet computers as the representative of consumer electronic products opened the first stage of the development of lithium battery; The development of electric vehicles has opened the process of the second stage of lithium battery, and the development of electric vehicles has also directly led to the application of lithium-ion batteries in electric bicycles, electric tricycles, low-speed electric vehicles and other means of transportation, and has now surpassed the 3C electronic products market and become the largest application market for lithium-ion batteries. The smart grid energy storage market will open the third stage of lithium battery. Each stage of development will bring geometric growth to the lithium battery market, at present, domestic and foreign government enterprises have increased research and development support, the global lithium industry is developing rapidly on new energy electric vehicles.

The rapid development of the lithium battery market has also directly led to the great development of the materials required for the manufacture of lithium battery (including cathode materials, anode materials, electrolyte, separator four key materials and other auxiliary materials), raw materials required for the manufacture of related materials and other industries, and has also rapidly increased the demand for resources required for the manufacture of these materials and raw materials.

1.2 Overview of the development of lithium battery industry in China

The development of China 's lithium battery material industry has gone through a process from scratch to completion. In 1997, Tianjin Lishen was registered and established, marking the beginning of the localization of lithium-ion batteries. Then BYD intervened in the lithium-ion business. TCL Jinneng, ATL, Bangkai, Advanced Electronics Energy, and Bike were successively established from 1999 to 2001, and the lithium-ion battery production team expanded rapidly. With the clustering and scale of the battery industry, the localization process of materials, raw materials and resources is also very rapid. In 2000, CITIC Guoan MGL was established, and the most critical cathode material opened the localization process; almost at the same time, the anode material project of Shanghai Shanshan achieved mass production, marking the beginning of the localization of anode materials. Since then, materials such as electrolytes, separators, lithium hexafluorophosphate, and lithium carbonate have been domestically produced. A number of world-class enterprises have emerged in China's key materials. While achieving self-sufficiency, a considerable part has been exported to overseas markets.

At present, the status of China 's lithium industry in the world is becoming more and more significant, and it has an increasingly important 'voice' in global lithium resources. In recent years, domestic lithium industry enterprises have actively deployed overseas, the lithium extraction process has been continuously upgraded, the production capacity has been expanded, and the cost has been reduced.

Selected graphical presentations in the report

For detailed report content browsing, please contact us

Annexes

Part 1: Introduction to cost and profit forecast methodology

Ø Historical Research:

CBC professional analysts conducted research on the reasons for the historical information changes of the target products, and selected the driving factors with strong influence based on the following three research directions:

² The degree and direction of impact on the cost of the target product

² Historical trend and current situation, predict future development trend

² Change rules, including seasonal changes and other regular changes

Ø Cost and profit forecast:

Based on the segmentation of cost items and price supply and demand changes, forecast future trends and inflection points, based on the long-term development trends of relevant products and background factors, CBC industry professional analysts adjust the trend.

Ø Explanation of influencing factors (not limited to the following aspects)

1. Cost account deconstruction and cost analysis

² Direct production costs:

ü Cost of raw materials

ü Cost of combustion auxiliary materials

² Tax cost:

ü Mine resources tax and fee

ü Production and processing taxes and fees

ü Additional taxes, etc.

² Complete production cost:

ü Cost of sales

ü Financial cost

ü Administrative costs

2. Profit influencing factors

² The influence of improving process on profit

² The influence of optimizing the ratio of raw material materials on profits

² The impact of providing personnel energy efficiency profits

² Impact of research on the use of alternatives on profits

² Technological development and iterative products

3. Background influencing factors

² Macro

² Policy

² Environment

² Global producer/consumer dynamics

² Logistics and Transportation

² Industry sentiment

Part 2: Introduction to CBC Research Data Sources and Methodology

Ø Principles of research indicators design

1 Based on the research needs and characteristics of the research, the design of the research indicators is scientific and perfect.

2 Indicators include: primary indicators: verification indicators; prediction assessment indicators; historical assessment indicators;

2.1 Basic indicators of the enterprise: that is, the basic information of the enterprise, the indicators checked by external data and researchers

2.2 Primary indicators: the information indicators directly investigated by researchers

2.3 Verification indicators: including two categories:

2.3.1 Category 1: that is, through the research of different enterprises on the same content, such as price, trade, pricing mechanism and other indicators, the research data can be verified through two-way or multi-direction, multi-channel research, so as to achieve the purpose of more real research information.

2.3.2 Category 2: that is, for the same research enterprise, by designing different indicators to verify the same research content; such as: capacity index, output index and capacity utilization index; (the capacity utilization index is the verification index)

2.4 Reference comment category, including two categories:

2.4.1 Category 1: Predictive assessment indicators: Since this project needs to forecast the next five years, the project team designed research indicators by analyzing various influencing factors and establishing parameter indicators, including qualitative and quantitative research requirements, in order to obtain more information for prediction assessment through research.

2.4.2 Category 2: Historical assessment indicators: Since this project needs to conduct research on historical five-year data, the project team designs the research indicators based on historical assessment. It is better if the primary historical data can be directly investigated; It is not possible to investigate directly, conduct research and assessment through historical assessment indicators.

Ø Data research methods (three types)

1 Primary Survey: understand the basic information of the company, product business scope, supply chain situation and development information, etc.

2 Refinement: refined research and verification, divided into products, sources, regions, flow directions, methods, etc.

3 Monitoring and research: Based on research targets (ie. research indicators and goals), full-dimensional, full-chain research deployment:

3.1 Full dimension: refers to conducting research on personnel in different positions in the enterprise, including production, sales, procurement, management and other positions, and conducting research, communication and verification on data;

3.2 Full-chain: refers to the research on the upstream and downstream of the industrial chain and related full-chain enterprises in the surrounding area.

3.3 Multi-method data validation

3.3.1 Based on IT technology, develop a data model to eliminate systematic deviations and data early warning: set a reasonable deviation rate for each data (the basis of deviation rate parameters), and test each data in each period.

3.3.2 According to the current market and the overall performance of the industry, expert analysts will issue alarms and check instructions for individual changes in the company.

Part 3: Medium and long-term price forecasts methodology

Ø Historical research:

[CBC Metal] Professional analysts conduct research on the reasons for the historical price changes of the underlying products, and select the driving factors with strong influence based on the following three research directions:

² The degree and direction of influence on the target product

² Historical trend and current situation, predict the long-term development trend

² Change laws, including seasonal changes and other regular changes

Ø Medium and long-term quantitative forecast:

Based on the changes in the supply and demand relationship, quantitative forecast of the long-term development direction trend and large change nodes, [CBC metal network] professional analysts adjust the quantitative trend according to the long-term development trend of related products and background factors

Ø Description of influencing factors (not limited to the following aspects)

1. Core influencing factors: supply and demand

² Supply side:

ü Direct impact: output, import volume

ü Indirect impact: capacity, start-up equipment dynamics

² Demand side:

ü Directly reflects: demand, export volume

ü Side reflects: apparent consumption, enterprise sales

2. Influencing factors of related products

² Upstream products (cost impact)

² Alternatives

² Technology development and iteration products

² Downstream products (product demand impact)

3. Background influencing factors

² Macro

² Policy

² Environment

² Global producer/consumer dynamics

² Logistics and transportation

² Industry sentiment

Part 4: CBC Platform Introduction

CBC Metal is based on the whole field of metals, basic materials and new materials, comprehensively tracking the industry development and technology frontier; it is committed to building a comprehensive and authoritative metal data platform, gathering domestic outstanding experts and scholars together to provide comprehensive data information services and decision support for metal industry research and practitioners, and is a famous industry data information service platform in China!

Its construction: 54 types of metal vertical portals and more than 18 types of new material industry chain platforms: including six base metals, 29 types of minor metals, eight precious metals, lithium new materials, photovoltaic, photoelectric materials, magnetic materials, catalytic materials, recycling, mining, new ceramics, refractory material industry, photoelectric material industry chain, rare earth industry network, ferroalloy industry chain, stainless steel industry chain, and other professional information service platforms.

Each type of platform is equipped with the corresponding research institute and data center; each field platform independently develops a large database system in the field, which is used for in-depth comprehensive system specialization for field content support and members' personalized needs and expanding specialized research.

It has a wide range of customer services and has a relatively high market share in government agencies, industry associations, listed companies, financial investment, industry research, the National Academy of Sciences, the Academy of Engineering and its branches and major colleges and universities at home and abroad, big data institutions, business strategy research institutions. The main domestic mineral enterprises, metals and related production and processing enterprises have been members of the site, while downstream users, trade services, equipment and technology and other business institutions members are also increasing.

Ø Complete system: large in volume, complete in information, and precise in classification, it is the most complete metal data application system in China at present.

Ø The data system includes six data modules. Each module is divided into several sub-modules, in order to meet the diverse information needs of customers.

Part 5:【CBC Metal】Part of the recent CBC member companies list for reference

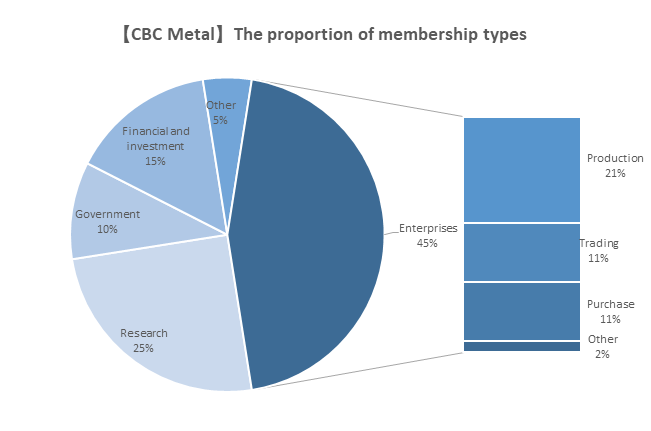

The current website membership of more than 300,000; daily visits to customers 30,000 ~ 50,000 IP; daily fixed browsing website high-frequency information, has established strategic cooperation with tens of thousands of professional institutions, enterprise groups, to provide timely and detailed and accurate industry information, relied on by customers!

CBC member customer classification

Ø Metal and material industry chain upstream and downstream enterprises; including mineral resources development, production and supply enterprises, internal and external trade enterprises, downstream purchasing user enterprises, technical service material enterprises, etc.

Ø Research institutions: including national, college-level, professional research institutions, professional research institutions in the field of metal materials, etc.

Ø Government agencies: national development planning, environmental protection, regional-level economic development, special park development service agencies, etc.

Ø Financial and investment institutions: including various securities, funds, banks, insurance institutions; various capital investment management institutions, etc.

Ø Big data service platforms and other classifications:

The proportion of customers of various services (schematic diagram)

Part 6: Introduction of Information Data Operation and Maintenance Organization System

The closed-loop organizational department structure enables scientifically detailed, accurate and professional data from research and development, construction, architecture, information access, daily collection, classification, validation, de-noising, de-cluttering, to systematic and logical publishing and external services.

Core business departments:

1. Enterprise Research Department

Provide a solid foundation for information collection and build a comprehensive and systematic information channels. Daily real-time communication with enterprises, obtain first-hand enterprise intelligence, comprehensive analysis and forecast of the market.

2. Analysts Department

Comprehensive understanding of the industry and the industry chain, forecasting and analysis of market conditions and prices.

3. Metal Research Institute and Data Center

Build metal data center, conduct professional and in-depth market research; Use scientific system industry big data base and global perspective to improve the overall industry development; Compile industry research report, provide enterprise personalized project services.

4. Business Department

Enterprise trade service, business matchmaking, enterprise publicity. One-to-one precise service, exclusive business manager provides manual trade matching services, 24 hours online, real-time monitoring of market dynamics, massive corporate database, global customer objectives, find the best customers for customers, to obtain excellent business opportunities.

5. Customer Service Center and After-sales Department

Serving customers, understanding their needs, providing professional services and targeted website products, answering and feeding back customers' after-sales questions in a timely manner.

6. Technical Department

Independently developed all kinds of database systems, chart systems, GIS systems, websites, APP and media platforms based on industry big data.